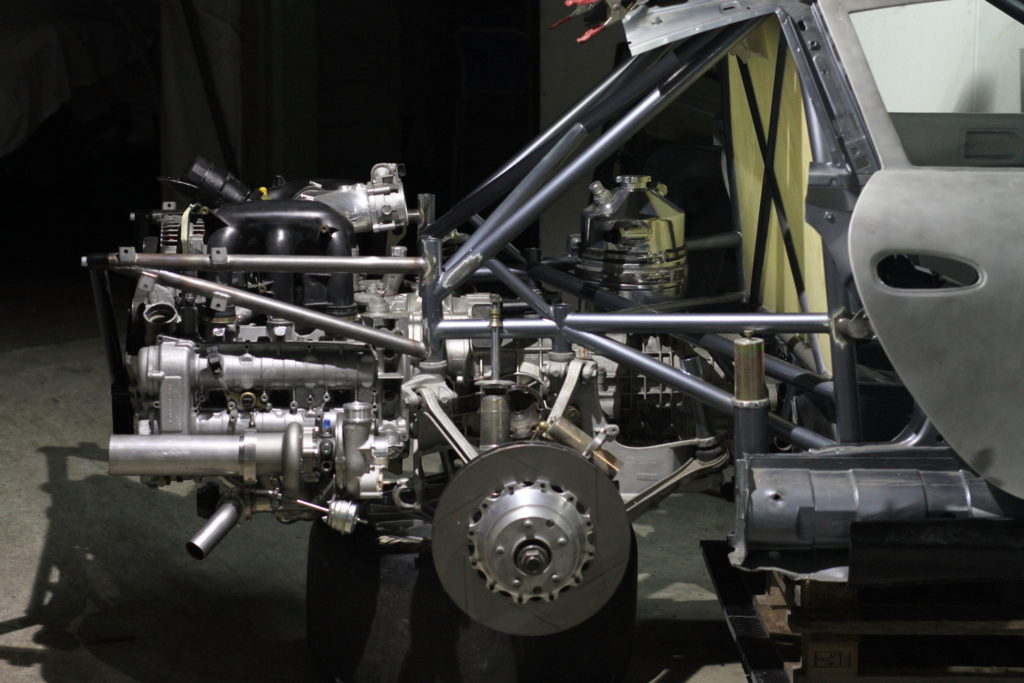

The GT2 has been moving ahead at a glacial pace! There is now a renewed push to get this car finished and on the track, so I dusted the cobwebs off the chassis and finished off the rear wing and engine mounts and a lot of those fiddly jobs that take so much time yet are never seen.

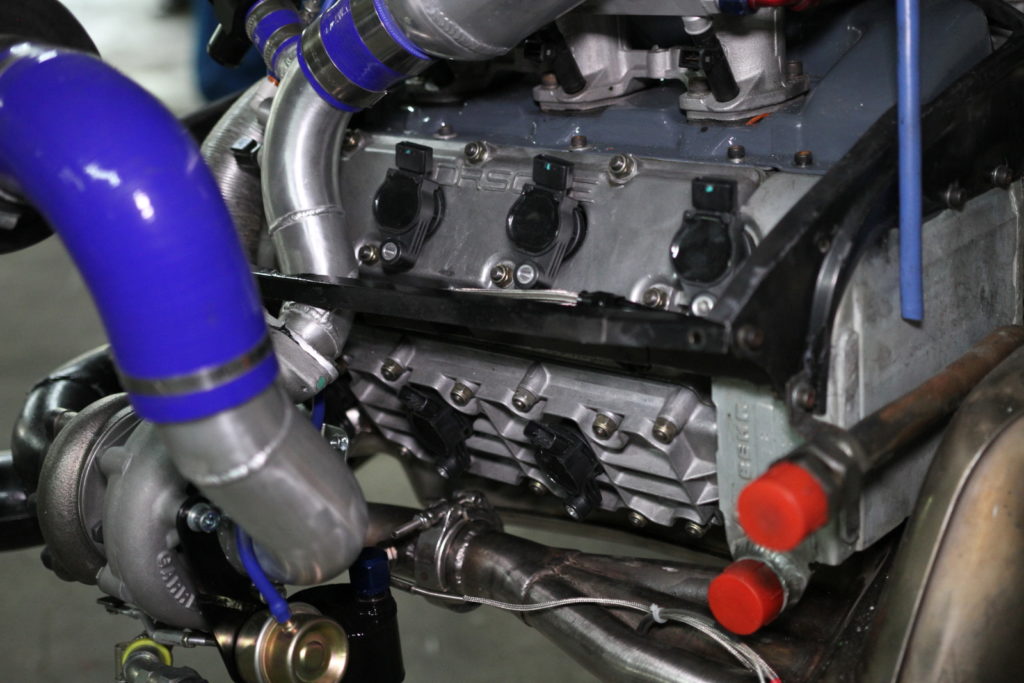

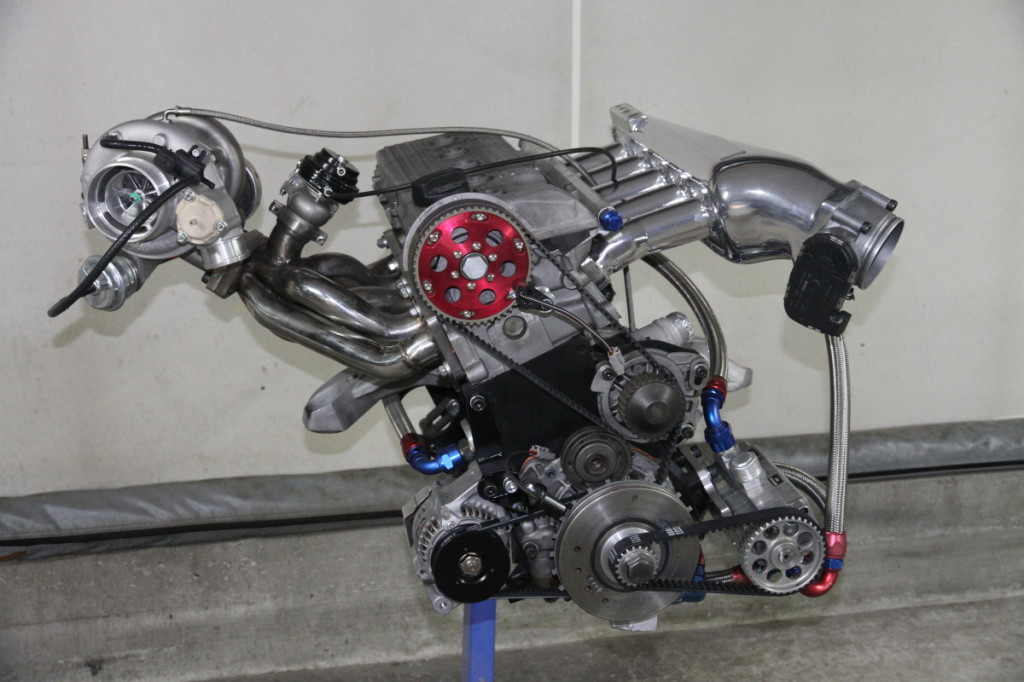

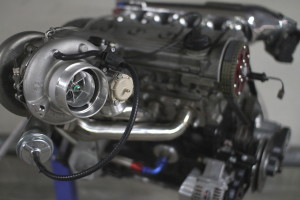

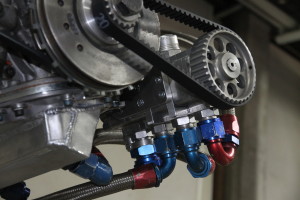

I decided to keep the turbos in a reasonably standard position but just make the headers so there was enough room for the external wastegates. It is a tight squeeze! There is just enough room so they don’t become intimate with the massive wheels when at full bump travel. It is simple and more efficient compared to the standard Turbo pipe work. The intercoolers have an o-ring seal onto the larger GT2 drive by wire throttle body to make mounting simple and the location is perfect to take advantage of the big roof mounted air scoop.

I am not looking to the next jobs of fabricating the fiddly firewall infill panels, replacing the firewall template with a carbon one with rear window, and then trying to work out how to mount the widened rear body work. It will be exciting to see it looking like a car again though!